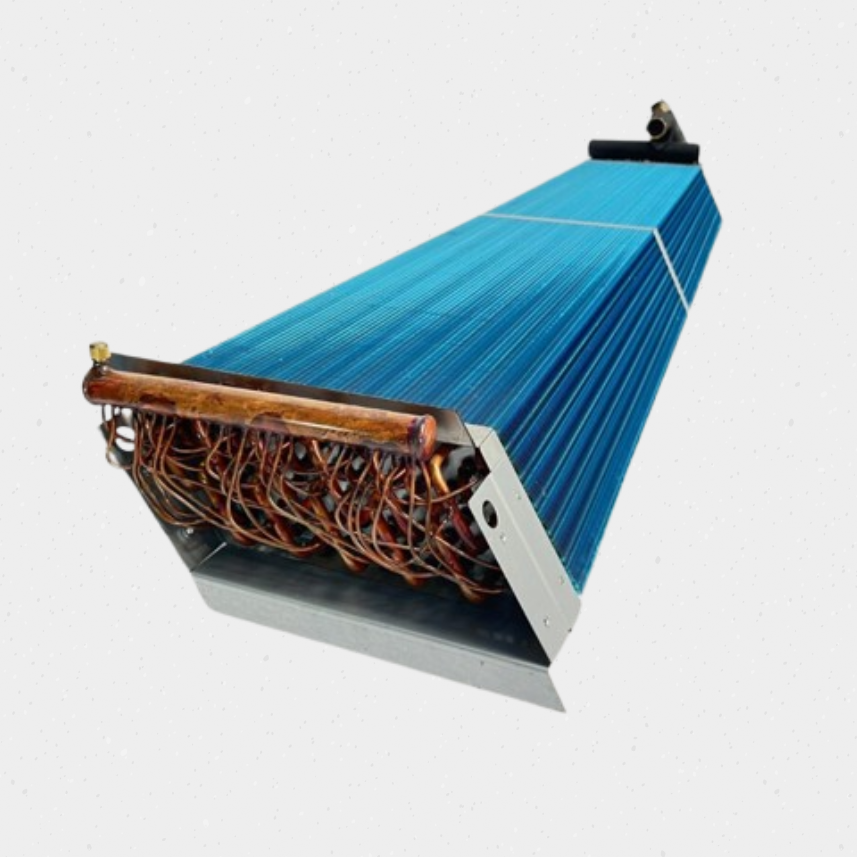

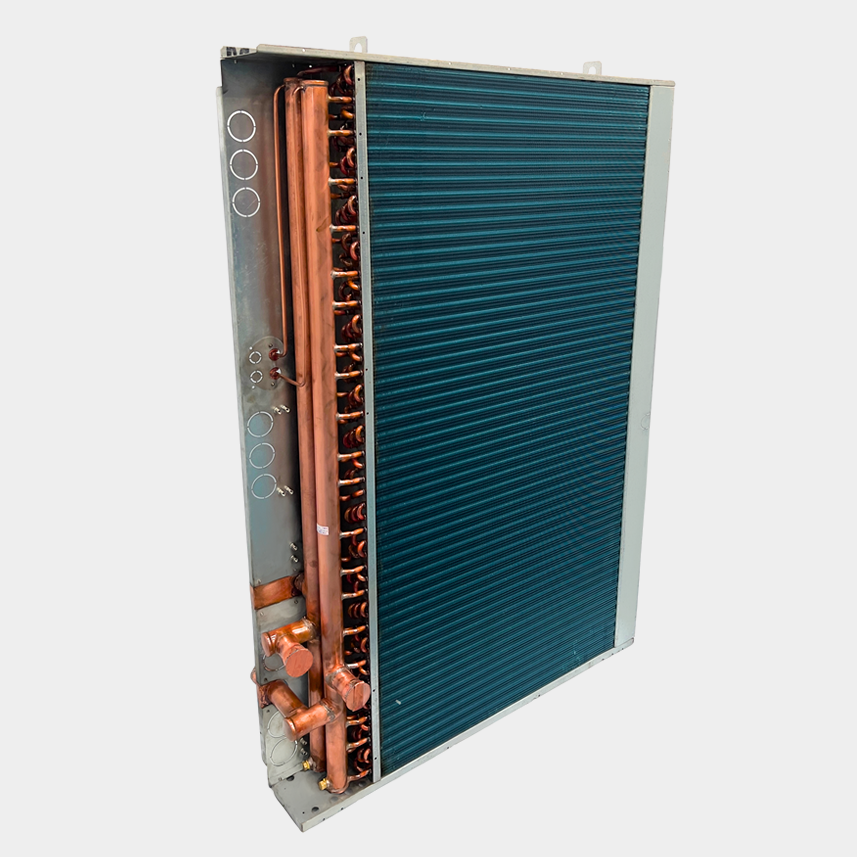

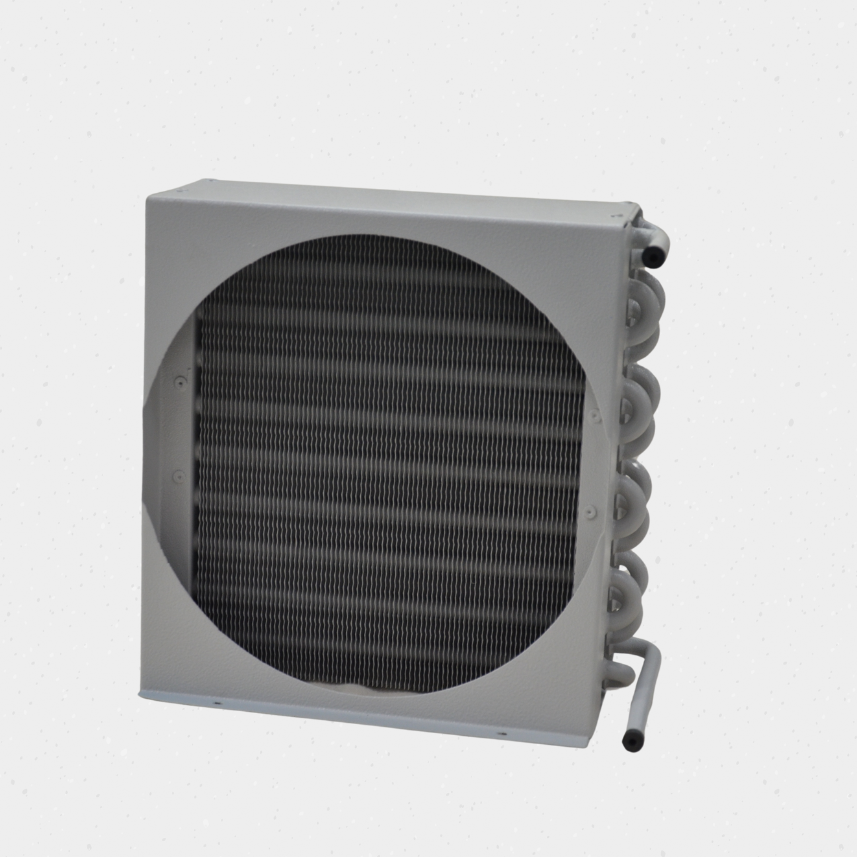

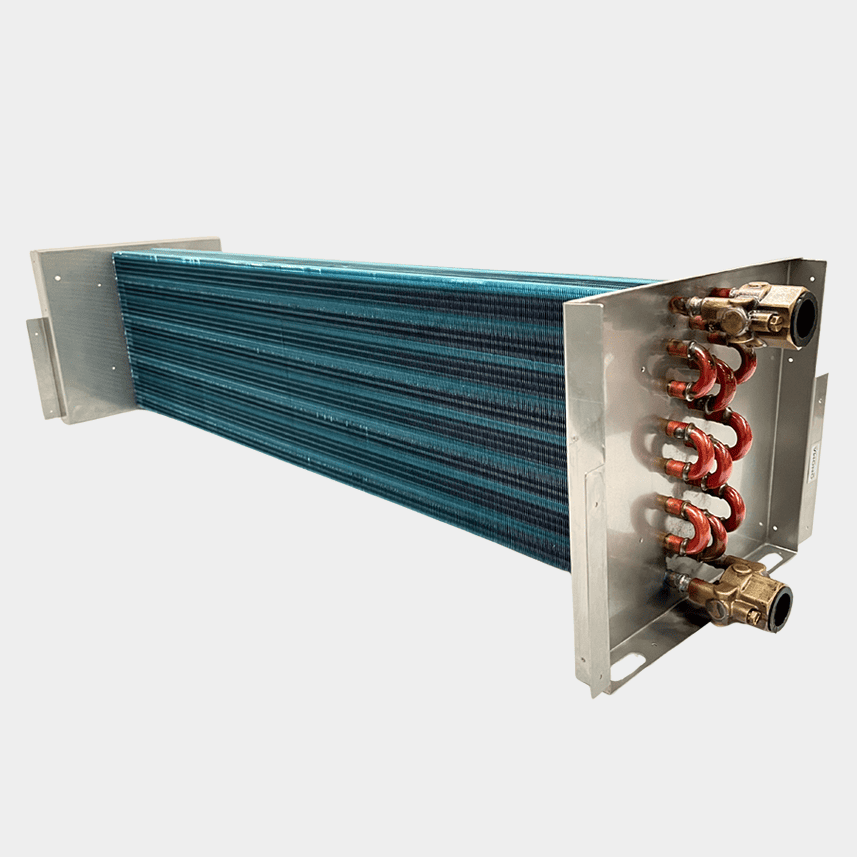

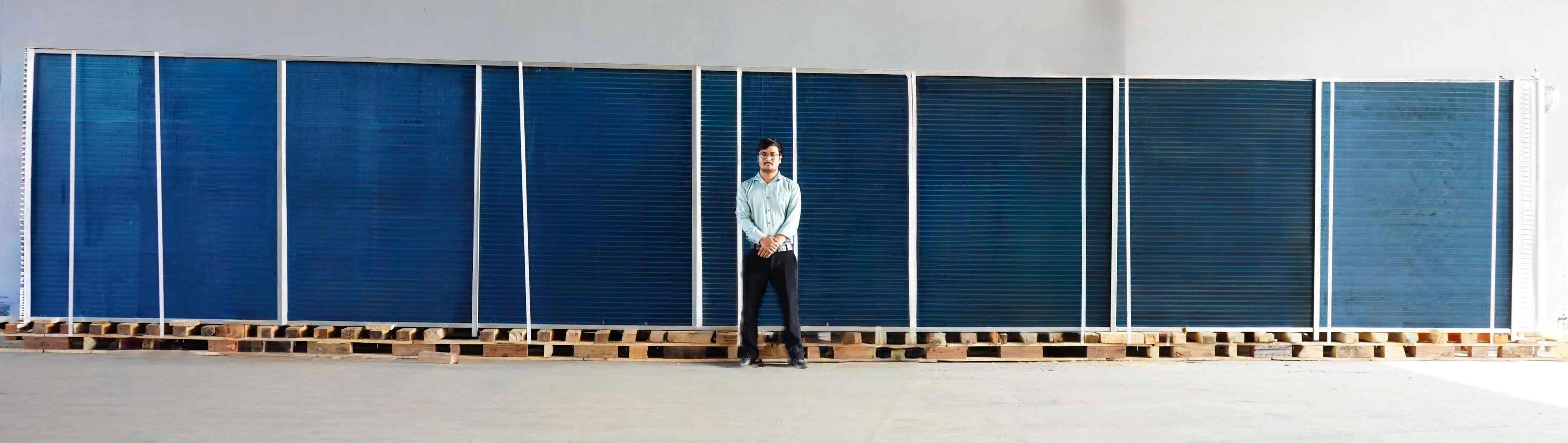

Coils Tailored to Your Needs

We offer a wide scope of customization to ensure our coils match your exact application requirements:

- Copper tubes – Plain & Grooved

- Copper & Aluminium fins – Bare, Hydrophilic, Hydrophobic

- Refrigerants & liquids – Chilled Water, Hot Water, Ethylene Glycol, Propylene Glycol

- Coil Casing – Cu, Al, GI, SS, Brass

- Fin Material – Aluminium and Copper

- Anticorrosion Coating – E-Coat, Heresite, OzKem, Nano, Tin, Powder or based on your specifications